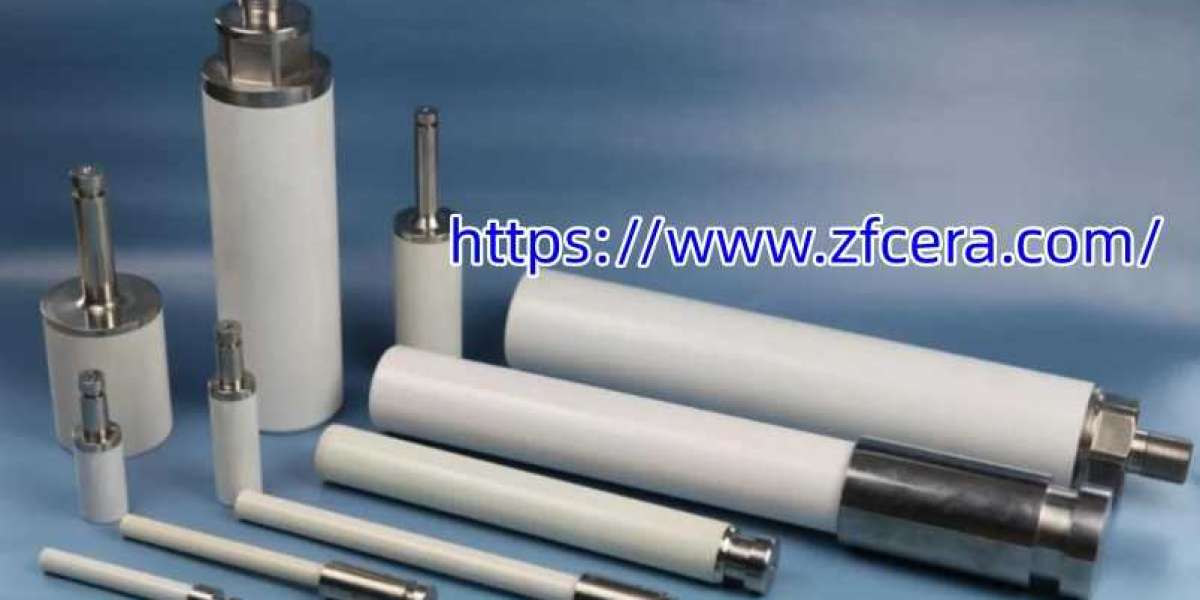

In industries that demand high durability and chemical resistance, zfcera offers advanced solutions through its Ceramic Plunger components. These components provide outstanding performance under extreme conditions, combining precise engineering with high-quality ceramic materials to enhance operational efficiency. Users gain extended lifespan, minimal wear, and consistent functionality, even in highly challenging environments.

Ceramic plungers are engineered from premium materials. Alumina ceramics deliver exceptional hardness and corrosion resistance, while silicon nitride provides thermal stability and mechanical toughness. These materials make plungers suitable for pumps, compressors, and specialized machinery. Reduced maintenance needs and improved reliability result from their superior properties.

Applications cover chemical processing, pharmaceutical production, and food industry machinery. These plungers can endure harsh chemicals, elevated pressures, and high temperatures without deformation or loss of integrity. Engineers value precise dimensions and smooth surfaces, which minimize friction and optimize operational efficiency. Implementing these components can streamline production cycles while maintaining safety and accuracy.

The production process incorporates modern techniques such as isostatic pressing, injection molding, and sintering to create dense, defect-free components. Each plunger undergoes rigorous inspection to ensure tolerance compliance, hardness, and surface quality. This combination of precision manufacturing and excellent materials surpasses traditional metal or plastic alternatives in durability and stability.

Additionally, these plungers demonstrate low thermal expansion, wear resistance, and stability under repeated mechanical stress. Industries relying on high-pressure pumping or precise metering benefit from improved flow consistency and reduced energy consumption. Their ability to maintain strict tolerances under variable conditions differentiates them from conventional solutions.

Environmental sustainability is another advantage. Long service life reduces replacement frequency and material waste, while some ceramic materials are recyclable, supporting resource conservation. Companies aiming for green manufacturing benefit from integrating these durable components into their processes.

Advanced design features also improve operational efficiency. Smooth surface finishes reduce friction losses, while the uniform density of materials ensures consistent performance. Engineers can rely on predictable behavior across different temperatures and pressures, enhancing safety and reliability in industrial operations.

Discover the advantages of zfcera's high-performance Ceramic Plunger components and explore how innovative materials and precision engineering can elevate your industrial processes by visiting www.zfcera.com