In modern pharmaceutical, electronics, and biotech environments, maintaining a controlled and sterile atmosphere is critical. Leading companies often rely on a Clean room Doors Manufacturer like yd-purification to deliver solutions that combine precision, durability, and advanced functionality. How does a single door system influence contamination control and operational efficiency so profoundly?

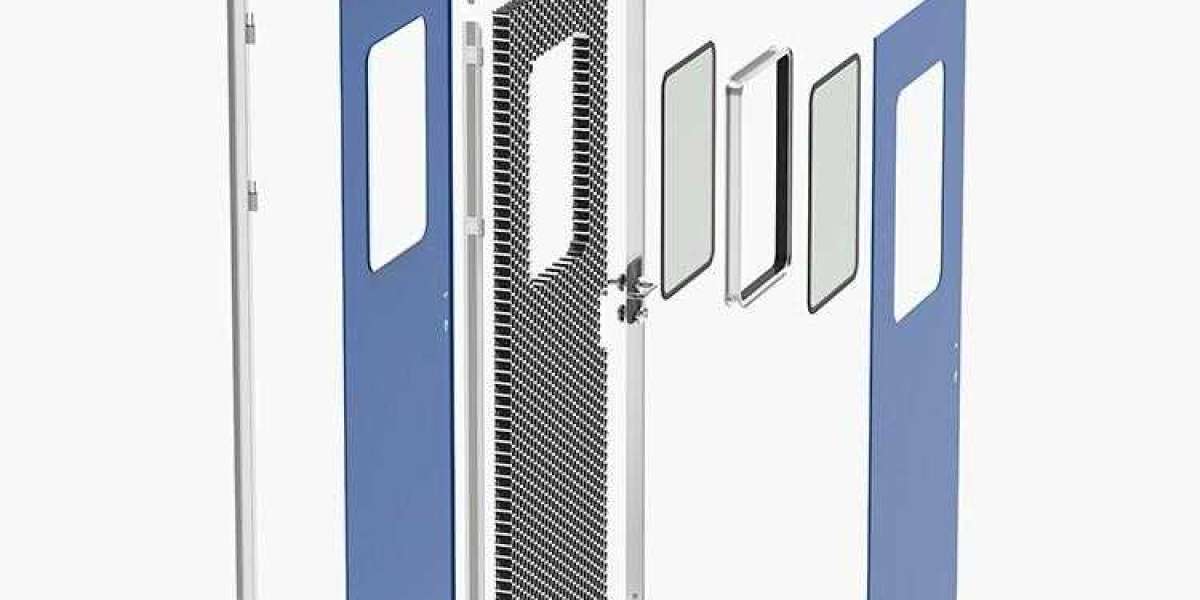

Cleanrooms are carefully engineered to minimize airborne particles and preserve strict environmental standards. Doors are more than entry points; they are integral to regulating airflow, pressure, and temperature while protecting sensitive processes. By incorporating advanced materials and seamless integration with filtration and monitoring systems, these doors provide a subtle yet essential layer of protection.

Selecting the right cleanroom door involves assessing both functional requirements and workflow patterns. Options range from sliding and swing designs to hermetically sealed units, all crafted with corrosion-resistant materials to withstand long-term usage. The flexibility of these designs ensures that facilities can adapt the doors to specific operational layouts without compromising hygiene or safety.

User experience and ergonomic design play a vital role. Doors must operate smoothly under frequent use while preserving internal pressure stability. Emphasis on silent operation, robust sealing, and low-maintenance performance reduces operational distractions, allowing staff to focus on critical processes rather than equipment concerns.

Automation has become an increasingly important aspect of cleanroom infrastructure. Integration with access controls and sensors enables doors to respond intelligently to personnel movement or environmental changes. Connection to centralized monitoring systems allows facility managers to track usage, anticipate maintenance needs, and optimize operational workflows. These technological capabilities ensure consistently high hygiene standards.

Sustainability also guides contemporary cleanroom design. Utilizing durable, recyclable materials and low-energy mechanisms helps facilities meet regulatory requirements while promoting environmentally conscious operations. Thoughtful engineering ensures a balance between performance longevity and eco-friendly practices.

From planning to installation and ongoing support, professional teams assist clients in choosing ideal configurations. Evaluations of spatial constraints, operational flow, and performance objectives enable tailored solutions that reduce risks while maximizing efficiency and sterility. This commitment to service underscores the brand's dedication to quality and client satisfaction.

Investing in advanced cleanroom infrastructure delivers long-term benefits. Well-engineered doors reduce contamination risk, minimize maintenance interruptions, and extend equipment lifespan. High-performance units maintain consistent functionality in demanding environments, safeguarding both productivity and safety.

For organizations striving for excellence in controlled environments, reliability and precision are essential. Yd-Purification's cleanroom doors represent meticulous engineering, rigorous quality assurance, and decades of expertise. They act as silent guardians of sterility and operational efficiency across industries ranging from pharmaceuticals to electronics manufacturing.For detailed information about Yd-Purification's Clean room Doors Manufacturer offerings, specifications, and configurations, visit: https://www.yd-purification.com/product/cleanroom-doors/